In the fast-paced world of packaging, efficiency is paramount, and one of the key players in this field is the stretch film machine. These machines have revolutionized how products are wrapped and secured for storage and transportation, providing a balance of durability and cost-effectiveness that is hard to beat. By stretching a film around goods, they not only offer protection from external elements but also optimize the use of space, making them an invaluable asset in warehouses and distribution centers.

As we look to the future of stretch film machines, advancements in technology continue to emerge, promising to further enhance their performance. From automation to innovative materials, the evolution of these machines is set to redefine standards in efficiency and sustainability. Businesses are increasingly recognizing the importance of investing in advanced stretch film solutions, designed to meet the demands of a growing market. By exploring these developments, we can gain insight into how the industry will adapt and thrive in the years to come.

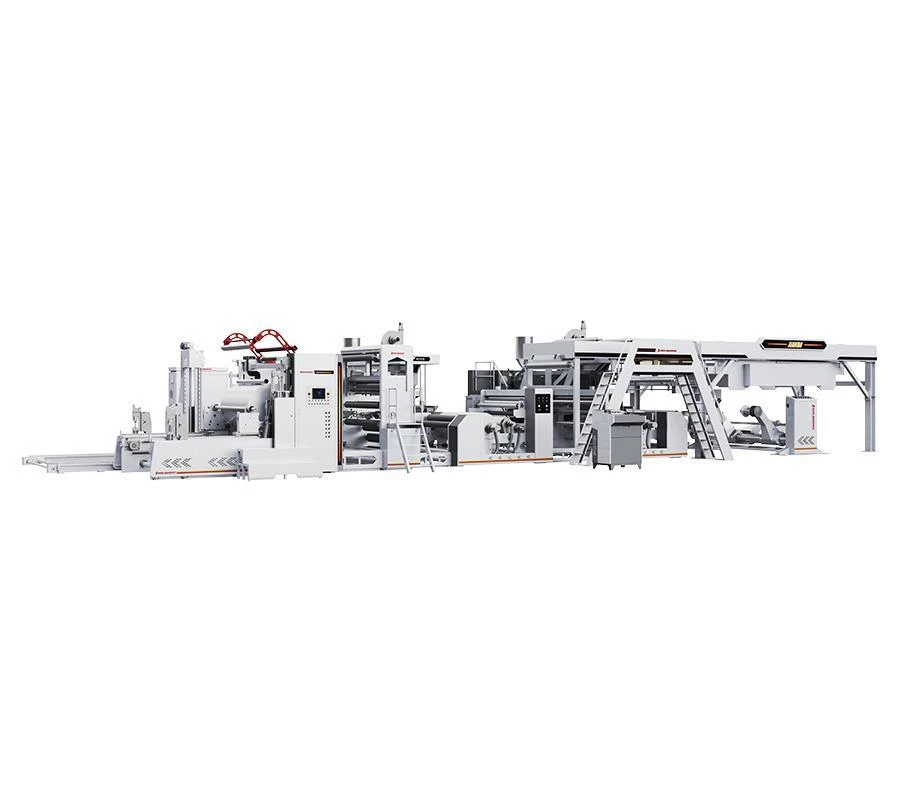

Technological Advancements in Stretch Film Machines

The evolution of stretch film machines has seen remarkable technological advancements that enhance efficiency and versatility in packaging processes. With the integration of automated systems, modern machines now feature advanced controls and sensors that optimize film usage, reducing waste and improving the overall packaging speed. These innovations allow for precise tension control, ensuring that the film is applied uniformly and tightly to the products, which enhances the protection during transit.

Moreover, advancements in materials and engineering have led to the development of more robust and durable stretch films. Manufacturers are now able to produce films that are thinner yet stronger, contributing to lower material costs while maintaining high performance levels. https://www.jiandajx.com/ minimizes environmental impact but also meets the demanding requirements of various industries in terms of load stability and protection against external factors.

Finally, the introduction of smart technologies in stretch film machines is revolutionizing the packaging industry. Machine learning and IoT integration enable real-time monitoring and predictive maintenance, reducing downtime and allowing operators to address potential issues before they escalate. With these smart features, businesses can improve productivity, enhance operational efficiency, and adapt quickly to changing market demands.

Benefits of Modern Stretch Film Technology

Modern stretch film technology brings significant advantages to packaging processes across various industries. One of the primary benefits is improved load stability. Advanced stretch film machines produce high-quality film that adheres tightly to products, reducing the risk of shifting during transportation. This protection not only maintains the integrity of the products but also minimizes the likelihood of damage, contributing to overall efficiency in distribution.

Another key advantage is the enhanced film elasticity and strength offered by contemporary stretch film. With innovations in material science, these machines are capable of producing stretch films that can withstand more stress and strain. This means that businesses can use thinner films while still achieving the same level of load security. As a result, companies can reduce their material costs and environmental impact, aligning with sustainability goals without compromising on performance.

Finally, modern stretch film machines often incorporate advanced automation and technology features that streamline the packaging process. Automated systems can adjust film tensions and application speeds in real time, ensuring consistency and efficiency. This not only speeds up the overall packaging operation but also reduces labor costs and human error, making the entire process more reliable and effective.

Conclusion and Future Outlook

As we conclude our exploration of stretch film machines, it is clear that these technologies play a crucial role in various industries. The efficiency and effectiveness of stretch film machines significantly optimize packaging processes, reduce material waste, and enhance product protection during transit. As businesses increasingly prioritize sustainability and cost-effectiveness, the demand for advanced stretch film solutions continues to rise.

Looking ahead, innovations in stretch film machine technology are poised to transform packaging practices further. Enhanced automation, integration of artificial intelligence, and the development of more environmentally friendly materials are just a few trends that promise to elevate the industry. Companies investing in these advancements are likely to stay competitive, meeting both their operational needs and the rising consumer demand for sustainable packaging.

In summary, the future of stretch film machines is bright, with a clear path toward greater efficiency and sustainability. As manufacturers and businesses adapt to these changes, the evolution of this technology will not only reshape packaging processes but also contribute to a more sustainable future for various industries. Embracing these innovations is essential for companies seeking to thrive in an ever-evolving market landscape.